What is a track circuit?

A track circuit is a section of a railway track that is electrically isolated from the rest of the track. It is typically used to detect the presence or absence of a train on that section of the track. Various rail control systems then use this information to manage the movement of trains and prevent collisions.

Track circuit operating device or TCOD?

A TCOD, or track circuit operating device, is a device that controls the electrical current flowing constantly through a track circuit. When a train is present on a track circuit, wheel axle acts as a conductor, allowing electricity to flow through it and complete the circuit. This causes a change in the electrical current flowing through the track circuit, which the TCOD detects. The TCOD then sends a signal to the rail control system, indicating that a train is present on the track circuit.

When the train leaves the track circuit, the electrical current returns to its normal state, and the TCOD sends a signal to the rail control system indicating that the track circuit is clear. The rail control system then uses this information to manage the movement of trains and prevent collisions.

TRACK CIRCUIT COMPONENTS

- Battery Charger 110V/2-10V DC

- Feed battery (1 to 4 cells)

- Fuse and link

- Regulating resistance (adjustable) 0-30 Ohm

- Type ‘B’ choke (R=3 Ohms & Z=120 Ohm)

- Track lead cable (2X2.5 sq. mm. copper).

- Track lead J.B.

- Track lead steel wire ropes

- Transverse bonds.

- Block joints.

- Track Relay (ACI).

Existing system of Track Circuit Maintenance

Battery charger, Feed battery cells, regulating resistance and Type ‘B’ choke are kept Apparatus Box which will be close to designated track circuit. Feed Battery consists of low maintenance flooded lead acid cells of 2 v which need periodical maintenance of topping up with distilled water. Regulating resistance need to adjusted manually if there is change in resistance due to whether conditions etc. Battery charger is constant voltage one without boost and float charging system.

If any of the above equipment not working, then track circuit will fail either in day or night indicating track circuit going red on SM panel and maintenance staff do not know reason for track circuit fail and they have to visit the failure site and physically check the reason for failure. It takes time to rectify the failure which may cause delay in train movement etc

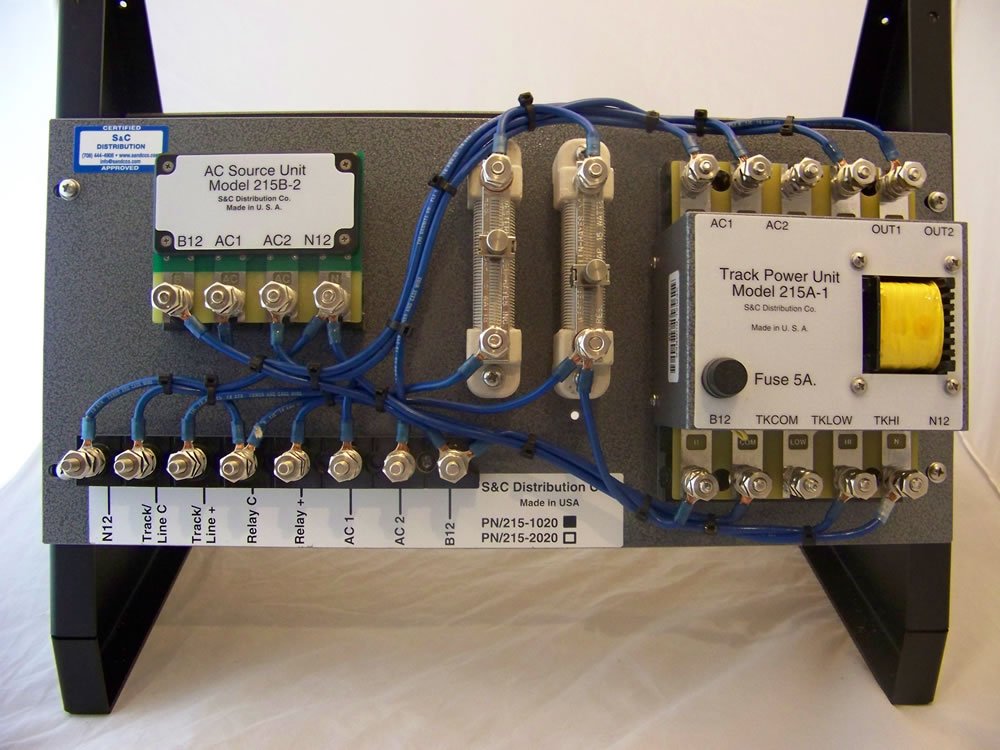

SAFE TRACK EQUIPMENT for track circuit:

consists of items – AC/DC to DC converter, Type ‘B’ Choke, regulating resistance unit, Rotary switch to select different resistances, Lithium-Ion battery, SMPS battery charger, SIM card-based PCB- in one enclosure unlike loose items kept in Apparatus case (Location box) near to track circuit (existing practice in IR).

How SAFE TRACK reduces fault rectification time

SAFE TRACK can automatically detect and alert maintenance crew through SMS to potential problems like – charger failure, input & output voltage failure, change in track resistance settings etc with the track circuit. Fast detection and alerting the maintenance crew can help prevent costly disruptions and delays of trains running.

Improves the efficiency of rail maintenance

SAFE TRACK allows staff to carry out their duties without waiting for trains to pass or be diverted to other tracks. The SAFE TRACK can help reduce delays and disruptions, which can be costly for rail operations and offer several benefits to the rail industry, including improved safety, efficiency, and reduced maintenance costs.