Ips – Cms – Complaint Monitoring System

WE ARE QUALIFIED IN EVERY WORKING DEPARTMENTS

QUALITY SERVICING OPPORTUNITY

A BMS enhances safety and reliability in battery-powered applications.

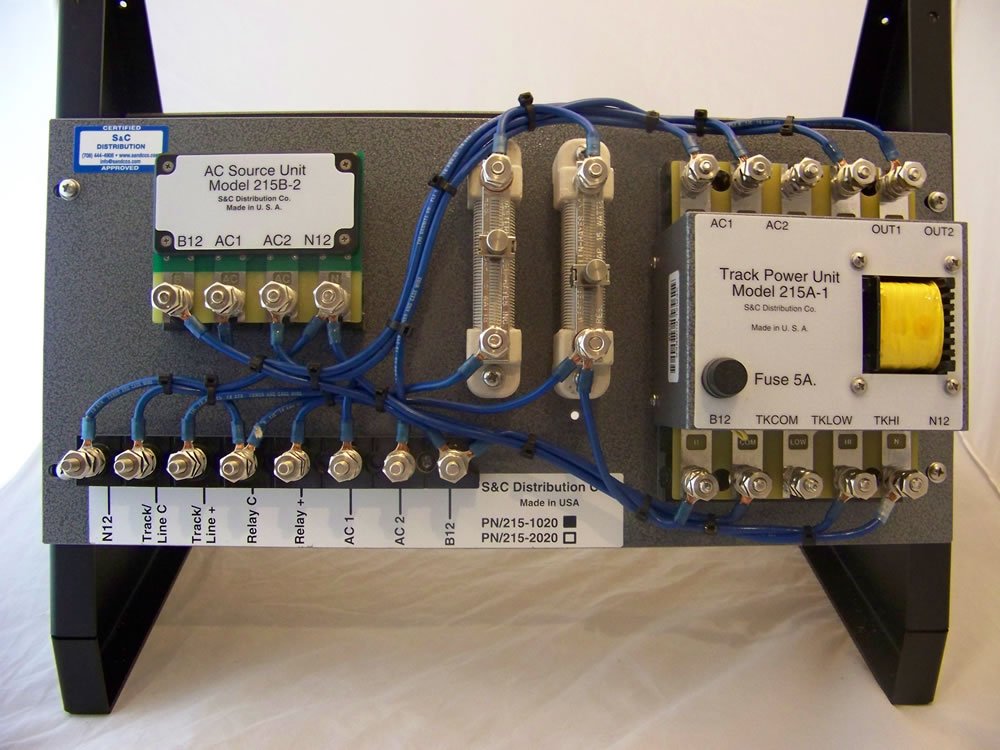

Battery charger, Feed battery cells, regulating resistance and Type ‘B’ choke are kept Apparatus Box which will be close to designated track circuit.

Present IPS population in Indian .Railway 7500 nos. Tracking the same for failures, closures, spares management

OUR RECENT WORK

-

WE ARE OPEN MONDAY-FRIDAY 9:00 am - 7:00 pm

-

HAVE A QUESTION? +91 91107 80021

-

FLAT – 2, 10-4-38/A/1, SURYA ARCADE, HUMAYUN NAGAR, HYDERABAD

OUR TEAM MEMBERS

EXCELLENCE DRIVEN FOR GETTING UNRIVALED RESULTS.

LATEST BLOG INSIGHTS

Frequently asked questions

BTY MONITORING SYSTEMS

What is a Battery Monitoring System (BMS)?

A Battery Monitoring System (BMS) is an electronic system that manages and monitors the charging and discharging of rechargeable batteries. It ensures the safety, longevity, and efficiency of the batteries by regulating their charging and discharging and monitoring the state of charge (SOC) and state of health (SOH) of each individual cell within the pack.

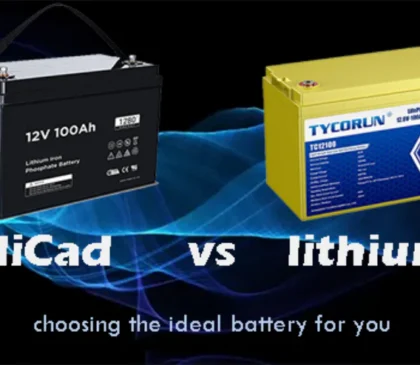

What are the differences of NI-CAD and Lithium batteries?

Here are some key differences between nickel-cadmium (NiCd) batteries and lithium-ion (Li-ion) batteries:

- Energy density:

- Li-ion batteries have a higher energy density than NiCd batteries, meaning they can store more energy in the same amount of space.

- Voltage:

- Li-ion batteries operate at higher voltages compared to nickel-cadmium batteries. A typical lithium-ion battery operates at 3.7 volts and a nickel-cadmium battery operates at 1.2 volts.

- Maintenance:

- Li-ion batteries are smaller in size, require low maintenance and are environmentally safer than Nickel-cadmium (also called NiCad, NiCd or Ni-Cd) batteries.

- Chemical composition:

- A nickel–cadmium battery uses cadmium for the anode (negative terminal), nickel oxyhydroxide for the cathode (positive terminal) and aqueous potassium hydroxide as the electrolyte. A lithium-ion battery uses graphite as the anode, lithium oxide for the cathode and a lithium salt as the electrolyte.

Why do I need a Battery Monitoring System?

A BMS is essential for maintaining the performance, reliability, and safety of your battery system. It helps prevent overcharging, over-discharging, and overheating, which can lead to battery failure and potential hazards. Additionally, it provides valuable data on battery performance and health, aiding in maintenance and preventing unplanned power outages.

What parameters does a BMS monitor?

A BMS monitors various parameters, including:

- Each battery’s cell voltage

- Battery bank net voltage & AH (Ampere-hour)

- Battery’s terminal temperature

- Ambient temperature

- Battery’s charging and discharging current

- Internal resistance at charging and discharging modes

- Online status of the battery bank.

How does a BMS improve battery life?

By continuously monitoring and analyzing battery parameters, a BMS can identify weak batteries or cells before they fail. This allows for timely maintenance and replacement, reducing the risk of sudden battery failure and extending the overall life of the battery system.

Can a BMS be used with different types of batteries?

Yes, a BMS can be used with various types of batteries, including lead-acid and nickel-cadmium battery systems. It records and transfers battery performance data, analyzes battery parameters, and generates reports that aid in battery protection and maintenance.

What are the benefits of using a BMS?

Some key benefits of using a BMS include:

- Real-time continuous monitoring of battery parameters

- Identification of weak batteries or cells before failure

- Remote monitoring of single or multiple battery banks

- Data logging and tailor-made log reports

- Audible and visual alarms for battery failures

- Improved battery performance and reduced maintenance costs.

How does a BMS communicate with other systems?

A BMS typically communicates with other systems via communication protocols such as RS485 and MODBUS. This allows for seamless integration with other monitoring and control systems, enabling remote monitoring and management of the battery system.

TECHNICAL QUIRIES & CLARIFICATIONS

How does the BMS measure the state of charge (SOC) and state of health (SOH) of the battery?

The BMS measures the SOC by monitoring the voltage, current, and temperature of the battery cells. It uses algorithms to calculate the remaining capacity of the battery. The SOH is determined by analyzing the battery’s performance over time, including its ability to hold a charge and its internal resistance.

What is internal resistance of a battery or cell?

The internal resistance of a battery is caused by the resistance of the materials that make up the battery. The electrodes and electrolytes are not perfect conductors, so they have some resistance (internal resistance) in them. The internal resistance is composed of Ohmic resistance and Polarization resistance, which depend on the materials, size, structure, and process of the battery. It indicates the battery’s ability to carry current. A low internal resistance means a high current, and vice versa. It also affects the battery voltage, which drops as the internal resistance and the load increase. The internal resistance varies with temperature and frequency of measurement. Ideally, a battery should have zero internal resistance.

Can the BMS be integrated with existing systems?

Yes, most BMS can be integrated with existing systems using communication protocols such as RS485, MODBUS, or CAN bus. This allows for seamless data exchange and remote monitoring.

What types of batteries are compatible with the BMS?

A BMS can be used with various types of batteries, including lead-acid, lithium-ion, nickel-cadmium, and more. It is important to check the specifications of the BMS to ensure compatibility with the specific battery type being used.

What is optimal temperature in batteries?

Different types of batteries have different optimal and acceptable temperature ranges for charging, discharging, and storing. For example, lithium-ion batteries may operate between 32°F and 113°F, while lead-acid batteries may operate between -4°F and 122°F . The standard rating for batteries is at room temperature 25°C (77°F). According to Fortress Power, the ideal operating temperature range for lithium batteries is from 50°F to 110°F. This range allows the battery to operate at peak performance while preserving its longevity and ability to function at highest capacity for 6,000 cycles. When allowing for 2,000 and 3,000 cycles, that range increases to 32°F up to 120°F. The optimal operation temperature for the battery may slightly vary with the battery type and design and it is within a temperature range of 25–45 °C. The ideal battery temperature for maximizing lifespan and usable capacity is between 15°C to 35°C. However, the temperature where the battery can provide most energy is around 45°C .

What is the temperature effect on battery?

Temperature has a significant impact on battery performance. High temperatures tend to decrease the capacity, charging rate, and life of batteries as they cause faster discharge and corrosion. On the other hand, low temperatures tend to decrease the capacity and performance of batteries as they increase the internal resistance and reduce the plates’ ability to retain charge. However, low temperatures can also increase battery life by slowing down chemical reactions. A study by Scientific Reports found that an increase in temperature from 77 degrees Fahrenheit to 113 degrees Fahrenheit led to a 20% increase in maximum storage capacity. However, there is a side effect to this increased performance: the lifecycle of the battery is decreased over time. Battery life is measured by repeatedly discharging and recharging at a test temperature above 167° F for 15 weeks or until performance drops to unacceptable levels. This simulates summer conditions in many parts of the country. I hope this answers your question! Let me know if you have any more questions

How does the BMS handle temperature fluctuations?

The BMS continuously monitors the temperature of the battery cells and the ambient environment. If the temperature exceeds safe limits, the BMS can take protective actions such as reducing the charging or discharging rate, or even shutting down the system to prevent damage.

What kind of data logging and reporting capabilities does the BMS have?

A BMS typically has data logging capabilities that record various parameters such as voltage, current, temperature, and internal resistance. This data can be used to generate reports and analyze the performance and health of the battery system.

How does the BMS alert users to potential issues?

The BMS can provide real-time alerts through visual and audible alarms, as well as notifications via SMS, email, or other communication methods. These alerts help users take timely action to prevent potential issues.

Can the BMS be used for remote monitoring?

Yes, many BMS systems offer remote monitoring capabilities. This allows users to monitor the battery system from a remote location using a web interface or mobile app.

What are the maintenance requirements for a BMS?

The maintenance requirements for a BMS are generally minimal. Regular software updates and periodic checks of the system’s components are recommended to ensure optimal performance. Additionally, it is important to keep the sensors and connections clean and free from dust and debris.